Latest Blog and Articles

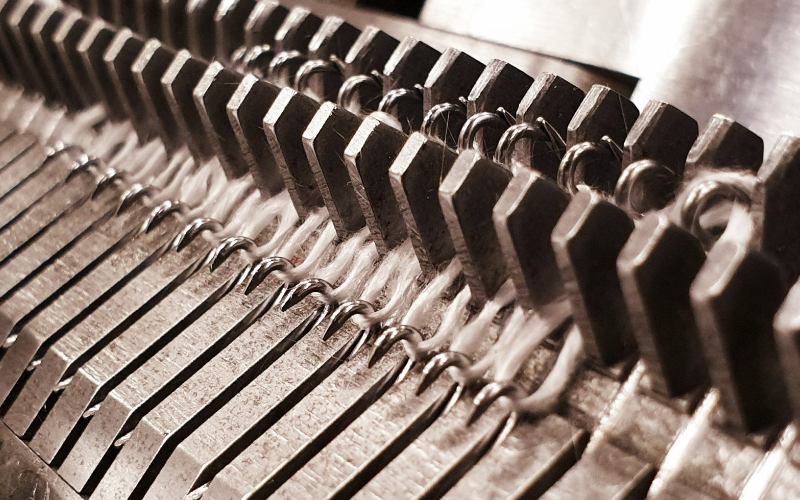

Sara Pullen, Managing Director of Pyroglass, invited me to the family owned independent organisation founded some 38 years ago. On entering Pyroglass, I was immediately impressed with the fine examples of glass fibre that adorned the walls throughout the building. Sara likes to tell people that Pyroglass is a knitting company, but as we open the doors of this Lancashire-based manufacturing plant, we discover there is a lot more to Pyroglass than meets the eye. Sara expanded, "We are in the business of knitting glass fibre that we use to produce a bespoke range of sealing and insulating materials capable of performing under extreme temperature conditions." I wanted to know more, so here is what I found out about the history of this exciting and innovative industry. Glass Fibre Knitting "Glass is an unlimited and innovative material that has plenty of applications. It is an essential component of numerous products we use daily, often without noticing. Glass continues offering cutting-edge solutions, including in combination with other materials. This trend is very likely to continue in the future". Source: Glass Alliance Europe When you think of knitting, what comes to mind? Sweaters, scarves and other clothing, right? Knitting is the process of making a textile by connecting loops or stitches of one continuous thread using needles. Pyroglass uses the same technique to produce knitted sweaters (by creating interlocking loops of yarn), but instead of wool they use texturised glass fibre yarns to form high temperature tapes, ropes and sleevings. Single glass fibres are very small (the largest being approximately one fifth of the diameter of a human hair ~9μm, each bundle of raw fibres may consist of thousands of individual fibres stranded together to form continuous fibre yarns which can be knitted. Glass fibre yarns have high tensile strength and can resist temperatures up to 550°C without losing structural integrity, making them an ideal component for many applications requiring high temperature sealing and insulation. "The Glass Industry in Europe is strong and diverse with 500 glass manufacturing plants, 500,000 jobs along the value chain, 25 European countries with glass production and 40 million tonnes of glass produced annually.” Source: Glass Alliance Europe Texturisation Process: Involves jetting streams of compressed air at the glass fibres, creating turbulence causing the formation of loops by overfeeding individual filaments which in turn mechanically bulks the strands. Texturising glass fibres improves thermal and acoustic insulation properties by creating air pockets within the stranded fibres, enhances the flexibility of the yarns so they can be knitted, increases the volume of the yarns for a “fluffier” finish and increases the abrasion resistance of the glass fibre. These features make texturised yarns particularly valuable in industries where high durability under heat stress is crucial, such as aerospace and automotive. High-Temperature Characteristics Glass fibre yarns are designed to withstand intense temperatures up to 550°C making them invaluable in industries requiring rigorous thermal management, such as automotive exhaust systems, aerospace engineering, fire-protective equipment, biomass boilers and incinerators. Safety and Reliability When exposed to such extreme temperatures, these glass fibre yarns maintain their tensile strength and flexibility, reducing the risk of failure in critical applications. This unique combination of properties places texturised glass fibre yarns in a category of their own when it comes to withstanding harsh environments. Cost Efficiency Longer lifespan in thermal environments means reduced replacement and maintenance costs. Incorporating texturised glass fibre yarns in your projects can enhance performance while ensuring safety and durability. It's a perfect example of how a seemingly simple innovation can have widespread, transformative impacts across many industries. The History of Fibreglass Venetian artisans used fine threads to adorn glassware in medieval times. Still, it was only during the Industrial Revolution that fine glass fibres were used for more reasons than just decoration. Here are some interesting facts I found from Science and Technology: 1836 , a Frenchman, Ignace Dubus-Bonnel, received the world's first patent for making glass fibres. 1842 saw a British silk weaver making a dress from glass fibre. 1872 , the Franklin Institute in Philadelphia reported that an engineer had produced "mineral cotton" by blowing a jet of steam through liquid glass, resulting in a white mass that could be suitable for insulating steam boilers and pipes. 1893 Edward D. Libbey of the Libbey Glass Company exhibited a fibreglass dress at the Chicago World's Fair weighing over 131 pounds (60kg). In the early 1900s, successful glass-blowing machines developed, helping to uncover the true potential of glass fibre. 1932 saw the first commercially successful product made from glass fibres, air filters for ventilating equipment that proved more capable of removing dust than cotton, especially popular with the increase in air conditioning equipment. But it was Slayter and Jack Thomas at Owens-Illinois who discovered a method of making glass wool for insulation. 1938 , Owens Illinois and Corning Glass joined forces and formed the Owens-Corning Fiberglas Corporation and subsequently produced a glass-wool insulation that was less expensive than mineral wool (or rock wool), making it the most popular insulating material of the time. Modern-day Applications of Glass Fibre In many ways, fibreglass acts like regular glass. It repels moisture; most acids and alkalis don't penetrate the filaments; it resists mould and mildew; it doesn't conduct electricity; it doesn't decay, rust, shrink, expand, or burn. Glass fibre is strong, solid and durable, making it ideal for many industries, including aviation, automotive, maritime and construction. Its non-combustible nature means it doesn't burn, smoke or emit toxic compounds when heated, which are characteristics important to the fire industry and domestic and industrial heating and cooking equipment. Glass fibre is a non-conductive and heat resistive material making it suitable for use around electrical components and wires, glass fibre is therefore an ideal component in numerous electrical and energy applications including solar, wind and PV systems, electrical components, insulators, housings etc. While glass fibre might seem like a new concept, its application in creating texturised yarns with high-temperature resistance has revolutionised numerous industries since the 1900s. Whether you're an industrial expert or someone curious about material science, understanding the development of glass fibre and its place in modern day industry allows us to appreciate innovations and their profound impact on technologies we encounter every day. Author: Lynne Rawlinson, Ribble Valley Marketing . Footnote: Pyroglass Limited was established in 1987 and remains an independently owned British manufacturing business with a wealth of experience in the design, production and marketing of specialist thermal materials. Pyroglass products are used worldwide for: • Domestic and Industrial Heating Equipment • Truck, Bus and Generator Exhaust Systems • Steel / Aluminium Smelting Plants • Hydraulic Hoses and Cable Systems • Cooking Equipment • Vehicle Electrical Wiring Harnesses • Oil Refineries and Oil Rigs • Thermal Acoustic Applications Please get in touch for more information on Pyroglass Knitted products.