Stoking the Flame: How Pyroglass is helping the quest for sustainable heating

Meeting Consumer Demands, Regulatory Changes, and Sustainability in a Growing Industry

Wood burning stoves continue to gain in popularity with UK homeowners, not just for their cosy and inviting appeal, but also because of the potential for reducing energy costs compared to traditional electric heating systems.

“The percentage of homes equipped with wood burners has risen from 9.4% in 2022 to 10.3% in 2024”. Source: UCL's analysis of energy performance certificates (EPCs)

However, the UK government's carbon plan, specifically the Clean Air Strategy and the Environment Improvement Plan, significantly impacts wood burning stoves by introducing restrictions and regulations aimed at reducing air pollution.

The regulations for new wood burning stoves insist that all new wood burning stoves and multi-fuel stoves and fireplaces that are manufactured in the United Kingdom must meet strict new guidelines referred to as Ecodesign.

“Unlike the requirements for Defra Exemption, which only applies to smoke control areas, Ecodesign regulations apply to the whole country, so no matter where a new stove is to be installed it must comply with Ecodesign.” Source: Stove Industry Association

The Ecodesign mark means the stove has been independently tested by an approved laboratory and meets requirements on air quality and particulates. Stoves are tested on seasonal efficiency (assessed over a year); levels of nitrogen oxides, carbon monoxide, particulate matter and organic gaseous compounds produced by burning fuel. An Ecodesign stove that’s properly installed and maintained and that uses good quality dry wood is a low carbon heating method using renewable and sustainable fuel.

Sustainable Stoves

The Department of Energy and Climate Change (now the Department for Energy Security and Net Zero) argues that burning wood for energy is carbon-neutral if it's part of a sustainable forestry practice where a new tree is planted for each one burned. This is because the carbon released during wood combustion was previously absorbed by the trees during their growth and will be reabsorbed by the replanted trees.

Modern wood burning stoves are designed to burn wood efficiently, producing more heat with less fuel. This high efficiency means that less wood is needed to generate the same amount of heat, reducing the overall carbon footprint. Additionally, using local wood reduces the emissions associated with transporting fossil fuels over long distances.

“As long as a new tree is planted for each one burnt as part of sustainable forestry, there are no added carbon emissions in total.” Department of Energy and Climate Change. Source: Creating Tomorrows Forests - Using Wood for Good – How Timber Can Help Fight Climate Change

Efficient Log Burning

Sara Pullen, Managing Director of Pyroglass UK said “Today's wood and multi-fuel stoves and gas fires are being designed increasingly with the emphasis on efficiency.

“A designer will look at all aspects of an appliance design to ensure the fuel is burnt efficiently and to achieve minimal heat loss through the flue/chimney and maximum thermal output into the room.”

Key considerations for efficiency include high temperature seals that maintain their integrity when operating at temperatures of up to 600°C. The seals help to ensure the right amount of oxygen enters the stove for complete combustion, maximising heat production and minimising smoke and emissions.

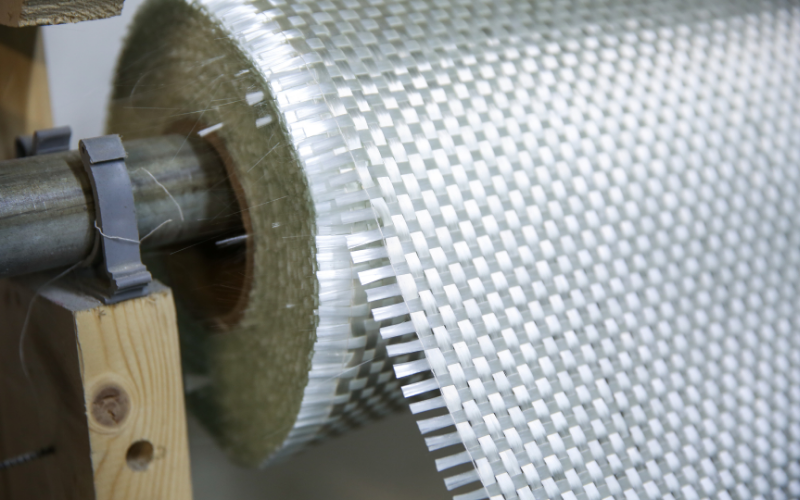

Pyroglass has been designing and manufacturing high temperature products in Lancashire for the heating industry for over three decades and it is their willingness to take on any seal design challenge that has kept them at the forefront of the industry. Their high-quality knitted stove door, window and ash pan seals can withstand temperatures of up to 600°C, their conformable and flexible properties ensuring an excellent seal between stove components.

Pyroglass high temperature products include glass fibre stove door, window and ash pan seals, custom made P seals and low viscosity high temperature adhesives.

Burning Smarter

The heating industry is well-positioned to thrive in the years ahead—especially for log burning stove manufacturers who adapt quickly to changing regulations. By focusing on eco-conscious design, modern aesthetics, and energy efficient innovation, you can fuel both customer satisfaction and business growth.

Now is the time to invest in product development, brand storytelling, and building strong relationships with the people who sell and install your stoves. Because in 2025, it’s not just about staying warm—it’s about burning smarter.

Pyroglass Limited has been designing and manufacturing high temperature seals for 35years. It is an independent, family-owned British manufacturing business willing to take on any seal design challenge from the heating industry.

To discuss your seal requirements, please contact us .